December30th

Distinguishing between hot-dip galvanized and electro-galvanized pipes can sometimes be challenging just by visual inspection, but there are a few characteristics and methods that can help you make an educated judgment:

Appearance:

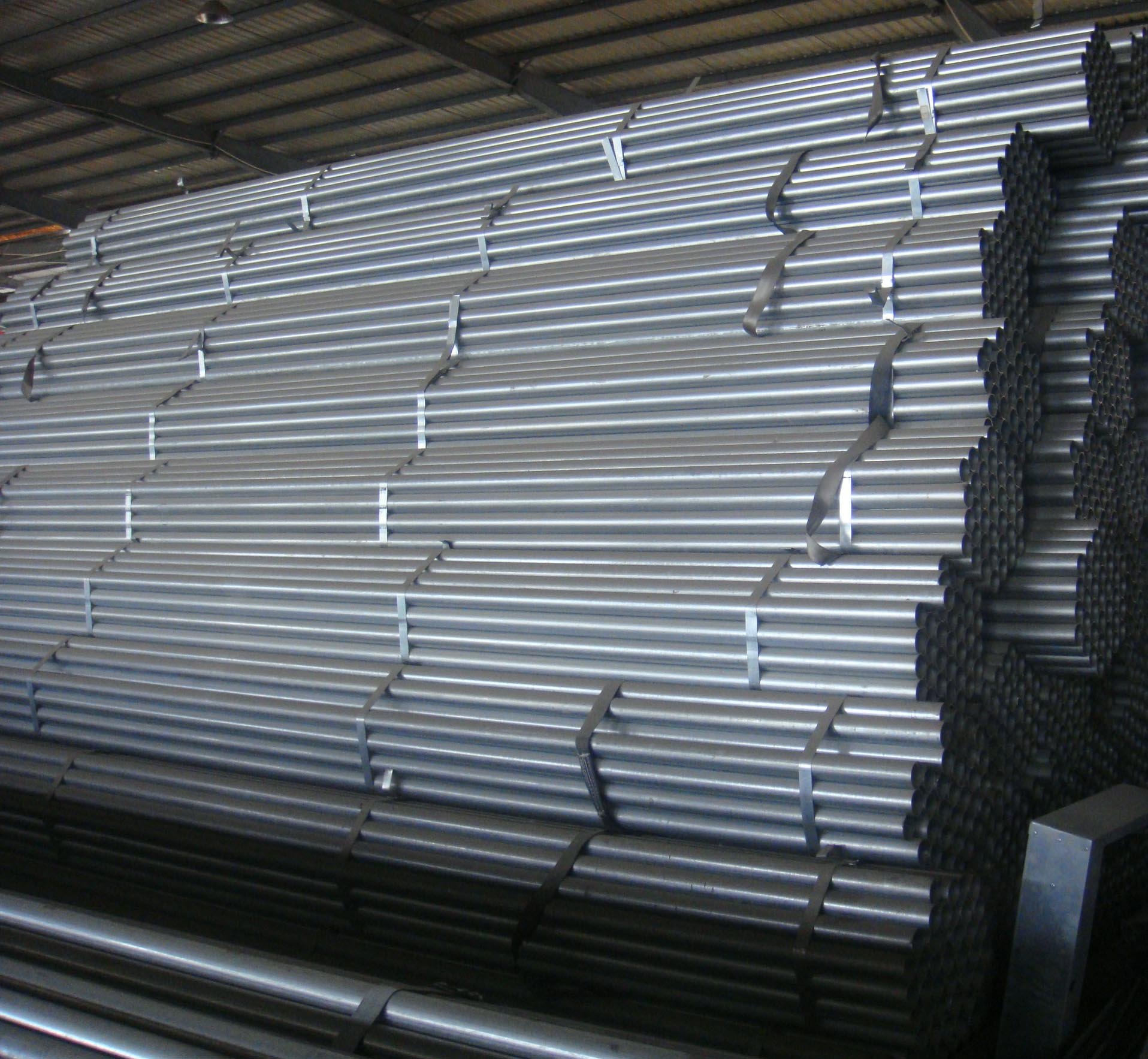

Hot-Dip Galvanized: Typically has a thicker and rougher coating. The surface may appear to have a spangled or crystalline pattern. The color is often a matte gray or dull silver.

Electro-Galvanized: Has a thinner and smoother coating. The surface is usually shiny and may have a more uniform appearance compared to hot-dip galvanized. The color tends to be brighter and more reflective.

Coating Thickness:

Hot-Dip Galvanized: Generally has a thicker coating, which provides better corrosion resistance. The zinc coating thickness for hot-dip galvanized pipes is usually specified in micrometers or mils.

Electro-Galvanized: Typically has a thinner coating compared to hot-dip galvanized. The coating thickness for electro-galvanized pipes is also specified in micrometers or mils.

Visual Inspection:

Hot-Dip Galvanized: Inspection may reveal a textured and irregular surface due to the zinc layers formed during the hot-dip process. The coating may have a crystalline appearance.

Electro-Galvanized: The surface tends to be smoother and more consistent due to the electroplating process.

Magnets:

Hot-Dip Galvanized: The thick zinc coating may make it less magnetic.

Electro-Galvanized: Since the coating is thinner, electro-galvanized pipes may exhibit more magnetic properties.

Corrosion Resistance:

Hot-Dip Galvanized: Provides better corrosion resistance, making it suitable for outdoor applications and harsh environments.

Electro-Galvanized: While still offering corrosion resistance, it may not be as durable as hot-dip galvanized in certain conditions.

Documentation:

Check Documentation: If possible, refer to any documentation or specifications provided by the supplier or manufacturer. This information is often available on product labels or in accompanying documents.

Ask the Supplier:

Contact the Supplier: If in doubt, the most reliable way to determine the type of galvanization is to contact the supplier or manufacturer directly. They should be able to provide information about the specific galvanizing process used for their products.

Remember that the terms "hot-dip galvanized" and "electro-galvanized" refer to different methods of applying a zinc coating, and visual inspection alone may not always be conclusive. It's advisable to combine visual inspection with other methods and consult the supplier or manufacturer for accurate information about the galvanizing process used for a specific pipe.